Tyre Pyrolysis Plant

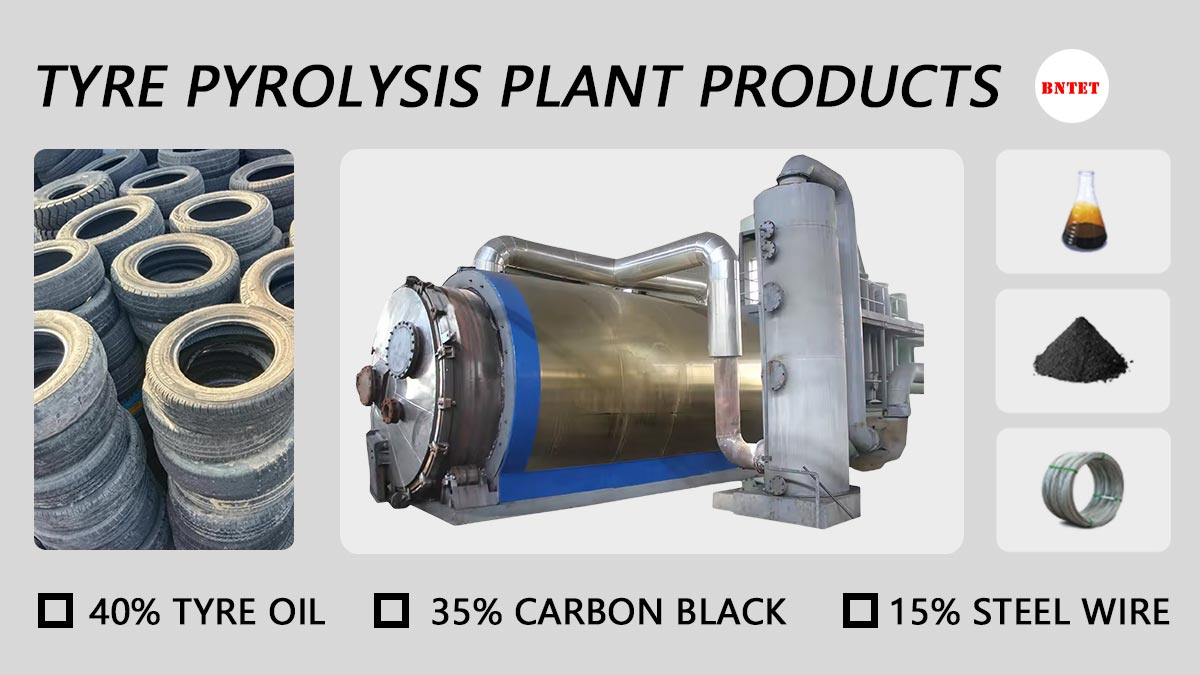

Tire pyrolysis plants can pyrolyze waste tires into carbon black, pyrolysis oil, steel wire and other resources.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Question 1-Product Description

Tire pyrolysis plants are specially designed to convert waste tires into useful products through a pyrolysis process.

Waste tire pyrolysis plants are also called pyrolysis oil plants because they decompose tires into tire oil.

Pyrolysis equipment thermochemically decompose organic matter under high-temperature, oxygen-free conditions, ultimately producing pyrolysis oil, carbon black, steel wire, and synthesis gas.

Question 2-Product Parameter

We can provide waste pyrolysis plants of various specifications, and we can also support customization for more requirements

| Model | BN-PR-3 | BN-PR-6 | BN-PR-10 | BN-PR-15 |

| Processing capacity | 3T | 6T | 10T | 15T |

| Reactor size(mm) | 1500*3500 | 2400*5000 | 2600*6600 | 2800*8000 |

| Pyrolysis time(h) | 3-4 | 4-6 | 6-8 | 8-10 |

| Feeding time(h) | 0.5 | 0.7 | 1 | 1 |

| Cooling time(h) | 3-4 | 4-5 | 4-5 | 5-6 |

| Discharging time(h) | 0.5 | 0.7 | 1 | 1 |

| Power needed(kw) | 12.5 | 18.6 | 32.5 | 35.5 |

| Water consumption(kg) | 100 | 300 | 500 | 500 |

| Fuel consumption(kg/h) | 30 | 40 | 60 | 90 |

| Area covered(W*L)m² | 2.3*11.5 | 8*22 | 8*30 | 8*30 |

| Application initial heating fuel | Natural gas/LPG/Diesel/Pyrolysis oil | |||

| Noise(dB) | ≤80dB | |||

| Working process | Batch type | |||

| Cooling method | Water cooling | |||

Question 3-Product Display

OUR ADVANTAGES

☆☆☆☆☆

1. Energy saving

The flammable gas that cannot be liquefied during the pyrolysis process can be transported to the heating and combustion system through the gas circulation system, which greatly saves energy.

2.Environmental protection

Through the well-designed gas circulation system and spray atomization dust removal system, the emission of greenhouse gases and the appearance of dust are greatly reduced.

3.Safety

Adopting advanced sealing system to oxidize the raw materials under oxygen-free condition, which greatly reduces the generation of toxic gases.

4.High efficiency

The reaction kettle can be rotated 360 degrees, and the whole furnace body is heated evenly, which greatly increases the cracking speed of the raw material.

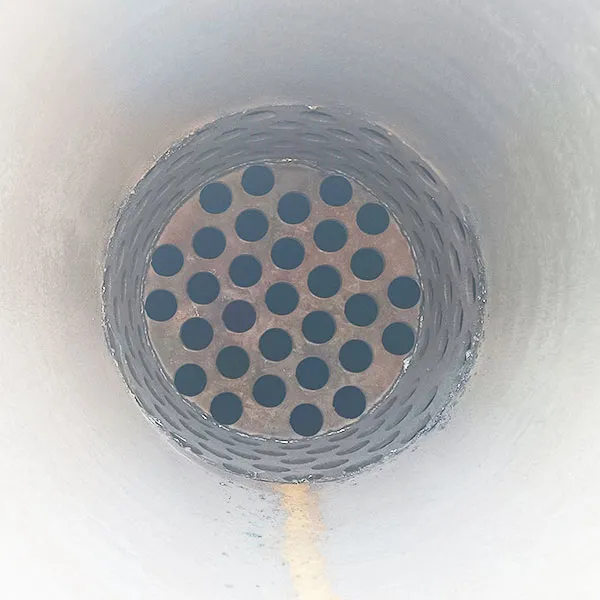

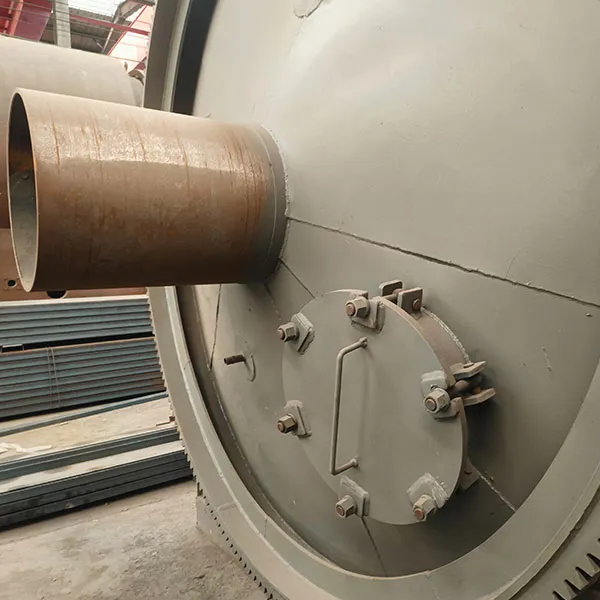

pyrolysis-plant-details-1

pyrolysis-plant-details-3

Question 4-Application

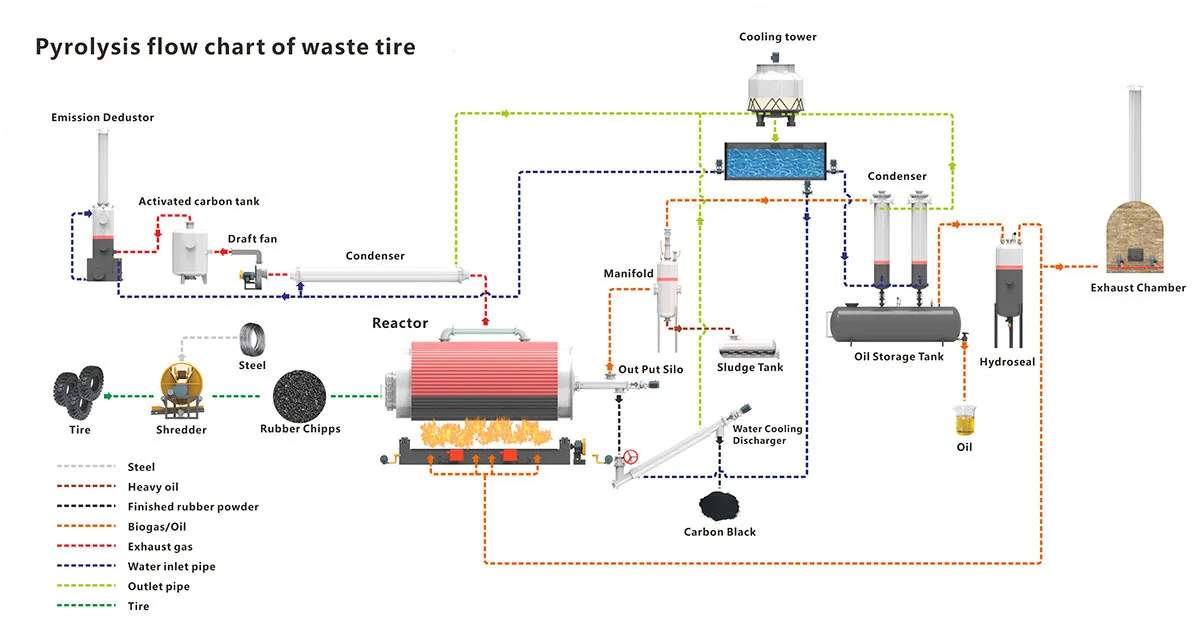

Tyre Pyrolysis Plant System Process Flow

1. Feedstock Pre-Treatment and Feeding System

2. Pyrolysis in the Pyrolysis Oil Plant Reactor

3. Steam Condensation and Oil Recovery

4. Processing and Collection of Carbon Black, Iron Wire, and Other Waste Tire Oil Plant Outputs

5. Environmental Management and Emission Control

Question 5-FAQ

Q:What is the difference between tire pyrolysis plant and plastic pyrolysis plant?

A:Plastic pyrolysis plant can be used to crack tires, but tire pyrolysis plant cannot be used to crack plastics.

Q:How long is the warranty?

A:One year, but we provide lifelong technical service and free software system upgrade.

More info....

Question 6-Our service

Hot Tags: Tyre Pyrolysis Plant

none

none