Tyre pyrolysis process flow

2025-07-25 17:24:11

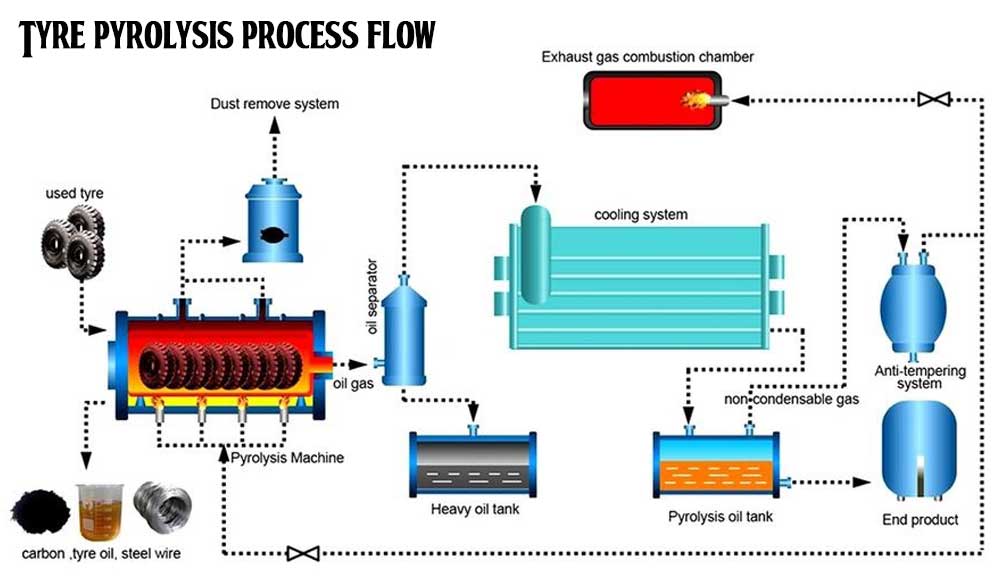

The tyre pyrolysis process converts waste tires into useful products like fuel oil, carbon black, steel wire, and syngas through thermal decomposition in the absence of oxygen. Here’s a step-by-step process flow:

1. Pre-Treatment (Tire Preparation)

Shredding/Crushing: Tires are cut into small pieces (2-5 cm) to improve pyrolysis efficiency.

Steel Wire Removal: Magnets separate steel wires for recycling.

Drying: Moisture is removed to enhance pyrolysis efficiency.

2. Feeding

Pre-treated tire chips are fed into the pyrolysis reactor via an automated or manual system.

3. Pyrolysis (Thermal Decomposition)

Heating: The reactor is heated to 200–450°C (optimal range) in an oxygen-free environment.

Decomposition: Tires break down into:

Pyrolysis oil (40-55%) – Used as fuel or refined further.

Carbon black (30-35%) – Used in rubber products, paints, or as fuel.

Steel wire (10-15%) – Recycled in steel industries.

Syngas (10-20%) – Non-condensable gases (methane, propane, butane) reused as reactor fuel.

4. Condensation & Oil Collection

Hot vapor passes through a condenser, where it cools into liquid pyrolysis oil.

Non-condensable gases are redirected to heat the reactor.

5. Carbon Black & Steel Discharge

After pyrolysis, carbon black is collected, cooled, and packed.

Steel wires are removed and sold as scrap.

6. Gas Recycling

Excess syngas is stored or used to sustain the pyrolysis process, reducing external fuel needs.

7. Emission Control

Scrubbers remove pollutants (H₂S, SO₂) from exhaust gases.

Charcoal filters capture harmful particles.

Final Products & Applications

Product Application

Pyrolysis Oil Industrial fuel, diesel refining

Carbon Black Rubber manufacturing, construction

Steel Wire Scrap metal recycling

Syngas Fuel for heating reactor

Advantages of Tyre Pyrolysis

Eco-friendly: Reduces landfill waste.

Energy recovery: Converts waste into fuel.

Profitable: High demand for pyrolysis oil and carbon black.

Challenges

Requires proper emission control to avoid pollution.

High initial setup cost for continuous plants.

Would you like details on batch vs. continuous pyrolysis systems?Please contact with me: info@bntet.com